We live in an era where doing something that was once “the only way” is now “the old fashioned way.” Technology that we couldn’t have even dreamed of at one point in time is now nestled politely in our pockets, disrupting quite literally every single aspect of our waking and unconscious lives.

And, because of that, sometimes using a pen and paper for something, rather than online or on a digital form, is seen as “the old fashioned way.”

But for a lot of applications, the “old fashioned way” is still the best way, even if it’s not the flashiest or newest.

“Obviously, there has been a lot of digital conversation over the last decade or more,” says Bob Saunders, vice president of sales at Wise Business Forms, Alpharetta, Georgia. “However, there are still some paper-based systems that work very well and make sense from a cost and workflow standpoint.”

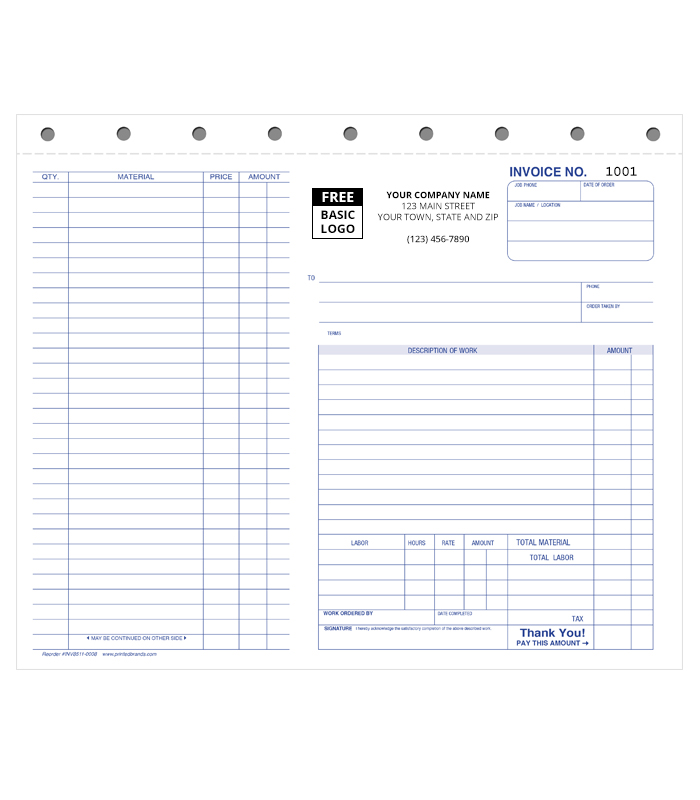

Saunders says that small-to-medium-sized businesses most often choose paper forms over digital as a cost-saving measure when digital systems are too expensive to justify. Depending on your customers’ lines of work, too, paper might be the preferred medium regardless of cash flow.

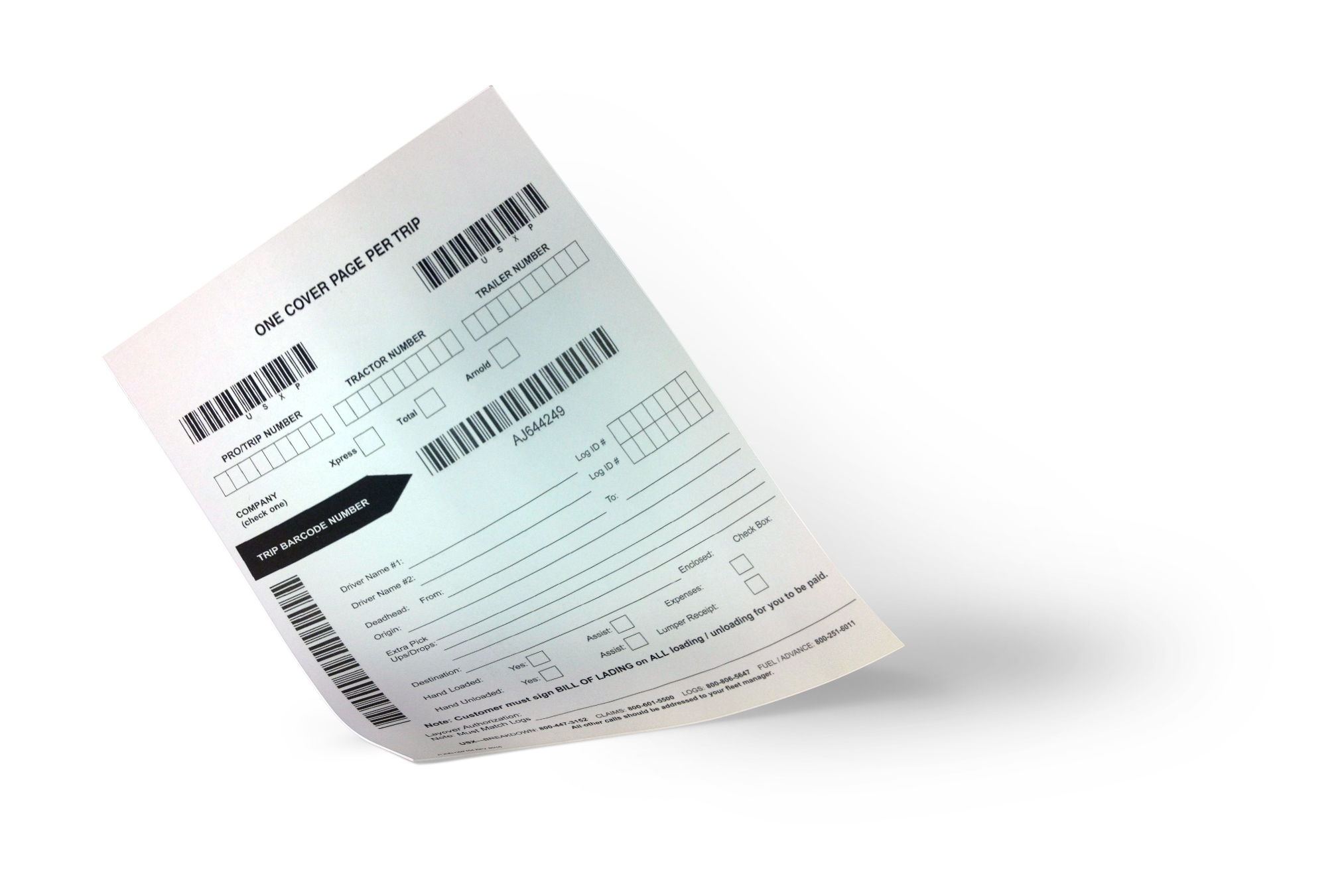

“There are also some vertical markets, such as automotive, where paper-based forms simply work better,” Saunders says. “Take the example of inspection forms: Auto technicians are often working with grease and oil on their hands, or they are wearing gloves, making paper-based forms far more practical than e-forms.”

We’ve all had to clean gunk off of our tablet or smartphone screens. If every mechanic had to do that with every job they were working on, your car would never get fixed.

And what about the times that technology fails us?

“Another example is field technicians,” Saunders adds. “There are still areas of the United States where there are dead spots for mobile service. Paper-based forms ensure that the tech will always have access to the forms they need while out in the field.”

That’s why my parents still like printing out MapQuest directions instead of relying on the smartphone GPS, I suppose.

Finally, Saunders says that sometimes paper forms are a matter of legality.

“Other businesses require paper-based forms from a legal or regulatory perspective — including accessibility,” he says. “Health care, financial services and legal services are just a few examples. Local, state and federal government agencies are also big users of printed forms.”

Combination Products

Within the traditional print sector, labels are some of the most reliable and consistent products for distributors. Technology has not been able to make them redundant. And, because print products like packaging can work together with other products to create a branded kit, labels fit into the business forms game for label/form combination products. Those are some of the most popular products for Sabrina Cherry, director of strategic accounts for Flesh Co., Parsons, Kansas. Many of the products, she says, are for the health care industry, where laboratory testing needs to be hyper-organized and documented.

“There will always be laboratory testing, so I do not see the products going away,” Cherry says. “I have seen many items reduce the number of parts required, changing from continuous format to cut sheets, and even some versions change to all pressure-sensitive material. As for the digital world, we are already producing the components to be ran digitally compared to traditionally. Several years ago, we expanded our offerings as well to be produced digitally through a program-based ordering system.”

The Product Is There

In 2020 and the years following, the supply chain was, putting it mildly, problematic. Paper shortages continued even as the world opened up, and printers and print distributors had to get creative. That is, largely, a thing of the past now, making print a little more appealing to distributors once again. It’s not without challenges, though, and Saunders says that it’s a good idea to maintain a good network of plants and alternatives for customers for when Plan B is necessary.

“The supply chain issues we all experienced a year or so ago have largely subsided,” Saunders says. “However, as the paper mills have reduced their number of SKUs, some of the specialty papers have had much longer lead times or have been eliminated all together. In those cases, we leverage our network of plants to see if we have paper to accommodate orders. Otherwise, we can offer paper alternatives that work.”

The Demand Is There

The most appealing thing about printed business forms, aside from the return of product availability, is that there’s no real “buying season.” It’s an evergreen product, to use a forestry pun.

Certain products do have upticks. Cherry notes that the COVID era made products for lab testing especially popular; and Kevin Mullaney, CEO and president of PDF Print Communications, Signal Hill, California, says that the end of the year is a particularly big time for their integrated card and long-run laser sheet products.

But, year-round, he says, their specialty products, such as carbonless snap-out forms, continuous forms, and laser-cut sheets singles and laser sets are in consistent demand.

“We also produce a large volume of integrated label forms that has been increasing in volume over the last five years,” he says. “All of our products help facilitate and complete the sales function of a large spectrum of industries that need these products to operate their business.”

And, on the topic of decreasing demand as a result of technological innovation, Mullaney says that it is an issue, but not as widespread as the naysayers would have one believe. It really depends on your customer base.

“There is no question that the digital world has drastically impacted the print space,” he says. “But we find the sharpest of these declines affects the Fortune 100 companies, which is not our core market.”

This echoes what Saunders said about costs dissuading some businesses from going purely digital. There are countless small-to-medium businesses that would prefer to do things with paper.

Mullaney says that there is one big tech innovation that has changed the way the company operates, though, and that’s the fact that some print methods eclipse others.

“The continuous form is the biggest evidence of [products changing over time], as it has been almost entirely replaced by a laser-cut sheet, or in some cases eliminated all together,” he says.

Saunders has seen similar evidence.

“If you have a multiple-part form, you may see a reduction in the number of parts required, or you may see a multiple-part form converted to a cut-sheet product to accommodate being run through a laser printer,” he says.

But, on the whole, a lot of the draw to this particular sector of print is the consistency.

“In most cases, the products stay the same,” Saunders says. “Not much difference.”